Category:

Small Sized Plastic Granulator / Plastic Grinder

Size reduction for soft plastics, molding plastic such as purgings etc. It is a compact and efficient industrial machine designed for the granulation of plastic materials in smaller-scale operations. Its size and portability make it particularly suitable for settings where space is limited, such as laboratories, small manufacturing facilities, or research environments. The machine's design emphasizes user-friendliness, allowing for easy operation and maintenance.

- Product description

- Main Features

- Application

- Specifications

-

Product description

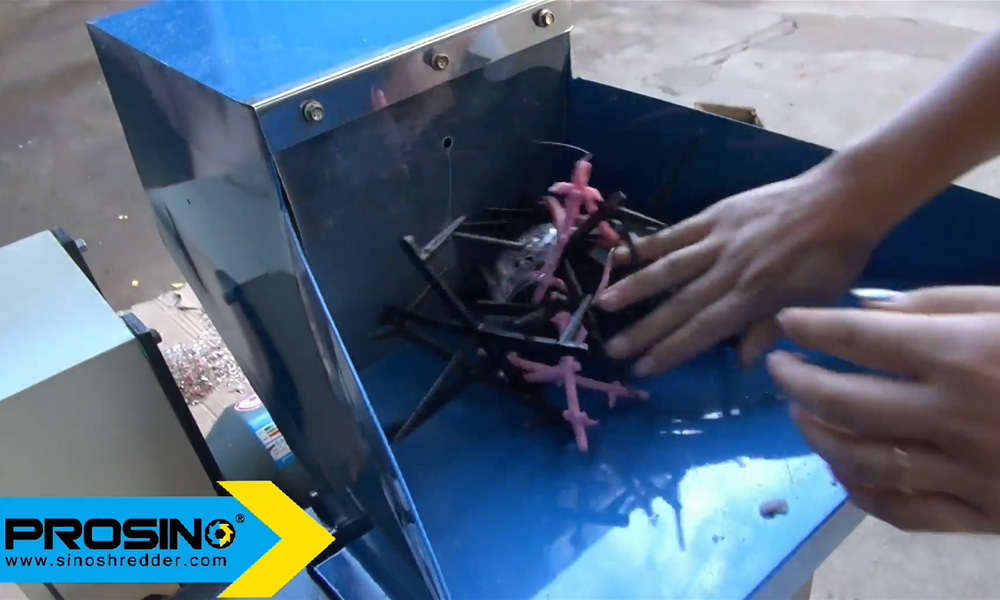

PROSINO PS-C-M Series Small Sized Plastic Granulator is also popular as plastic grinder. It features with compact design and small footprint. This is a popular granulating machine mainly used in small-scaled recycling facilities. It is also adopted by some manufacturing plants as a solution of internal waste management. Those small-sized plastic granulator machines are specialized in granulating/crushing small size plastic (soft plastic & hard plastic) and rubber material, including PET bottles, HDPE sanitary containers, nylon, molding sprues, molding runners, purgings, PP sheets, plastic packaging, rubber rings, rubber sheets etc.. No matter the scrap material before granulating is in the forms of ball, block, strips, or sheets, this series granulators can easily handle it with high efficiency. A screen is mounted at the discharging port of the machine to control the crushed granules below certain size. So it can make the final granules suitable to be processed in next recycling step.

Contact us today and our PROSINO Granulator team will recommend the most suitable models for your own size reduction purpose. View plastic balers if you are interested in.

Key words:- small granulator

- plastic granulator

- plastic crusher

- small crusher

- plastic grinder

-

Main Features

- Blades made of high-resistant steel

Ensuring longest usage times - Hopper, cutting chamber, and discharging base are separable

For convenient cleaning, parts replacement, and maintenance - Double sound-insulation device in the cutting chamber

Reducing noise to the minimum - Air extraction & collection system is optional

For conveniently collecting the final granules into bags or containers - Blades can be sharpened for several times after getting blunt

To extend blades’ lifespan and save cost - Motor over-load protection and interlocking device

Well protecting machine itself and ensuring operator safety

- Blades made of high-resistant steel

-

Application

- PLASTIC

PET bottles, HDPE containers, plastic pipes/tubes, nylon scrap, PP sheets, plastic packaging, molding scrap(sprues, runners, purgings) - RUBBER

Hoses, Rubber sheet, rubber pad, rubber tube (e.g. tire inner tube), bicycle tire, rubber block, rubber seals - PAPER

Cardboard, newspaper, office paper, kraft paper, paper core, cardboard tube, paper packaging - WOOD

Wood lump, tree branch, slat

- PLASTIC

-

Specifications

Model Hopper Inlet Active rotor diameter Main motor power Weight(approx) Length Width PS-C-M-1823 250 mm

(10 inch)

160 mm

(6 inch)

ø225 mm

(ø8.9 ")

4 kw

(5 HP)

250 kg

(550 lbs)

PS-C-M-2231 320 mm

(13 inch)

200 mm

(8 inch)

ø240 mm

(ø9.4 ")

5.5 kw

(7.5 HP)

290 kg

(638 lbs)

PS-C-M-2541 420 mm

(17 inch)

220 mm

(9 inch)

ø270 mm

(ø10.6 ")

7.5 kw

(10 HP)

420 kg

(924 lbs)

PS-C-M-3051 520 mm

(20 inch)

300 mm

(12 inch)

ø280 mm

(ø11.0 ")

11 kw

(15 HP)

550 kg

(1210 lbs)

PS-C-M-3261 620 mm

(24 inch)

270 mm

(11 inch)

ø350 mm

(ø13.8 ")

15 kw

(20 HP)

750 kg

(1650 lbs)

PS-C-M-4082 820 mm

(32 inch)

500 mm

(20 inch)

ø400 mm

(ø15.7 ")

30 kw

(40 HP)

1700 kg

(3740 lbs)

PS-C-M-40100 1020 mm

(40 inch)

600 mm

(24 inch)

ø400 mm

(ø15.7 ")

37 kw

(50 HP)

2500 kg

(5500 lbs)

PS-C-M-40120 1220 mm

(48 inch)

600 mm

(24 inch)

ø400 mm

(ø15.7 ")

45 kw

(60 HP)

3000 kg

(6600 lbs)

KEYWORD

All Shredders and Granulators

Categories by Number of Rotor

Categories by Function

Auxiliaries

Related video

PET Bottles Granulator, PET Bottle Grinder, PET Bottle Granulator

Injection Runner Granulator, Plastic Runners Granulator, Plastic Injection Runner Grinder

Fiberglass Granulator, Fiberglass Granulating Machine, Fiberglass Grinder

The above machine can shred/granulate

Shredders and Granulators

RELATED EQUIPMENT AND ACCESSORIES

I agree that my personal data collected by PROSINO is processed, used and stored in compliance with data protection exclusively for the purpose of processing my request.

SINOSHREDDER PRIVACY POLICY

We collect information from you when you fill out an inquiry or contact form. When submitting the form on our site, you may be asked to enter your name and contact details such as: e-mail address, mailing address and/or phone number, etc. Alternatively, you can choose not to complete our forms and visit our site anonymously. Any of the information we collect from you may be used to help us to better respond to your individual needs, and/or enable us to more effectively respond to your customer service requests and support needs. The email address you provided may also be used to send you information and updates pertaining to your inquiry and/or order, in addition to receiving occasional company news, updates, related product or service information, etc.

PROSINO SHREDDER does not sell, trade, or otherwise transfer to outside parties your personally identifiable information. This does not include trusted third parties who assist us in operating our website, conducting our business, or servicing you, so long as those parties agree to keep this information confidential. We may also release your information when we believe release is appropriate to comply with the law, enforce our site policies, or protect ours or others rights, property, or safety.

By using our site, you consent to our online privacy policy. If we decide to change our privacy policy, we will post those changes on this page. If you have any questions or concerns regarding our privacy policy, please e-mail prosino@sinobaler.com or mail your question to us at 1206 Yinzhou Shanghui Nan Lou, 1299 Yinxian Avenue, Yinzhou District, Ningbo 315192, P.R. China.

EXTERNAL LINKS & DISCLAIMER

Our web site has links to many other organizations with their permission. Upon leaving the SINOSHREDDER web site, you are subject to the privacy policy of the new site which are not under our control. PROSINO SHREDDER is not responsible for the content of any linked site or any link contained in a linked site. These links are provided to you as a service for you to better understand the different business relationships that SINOSHREDDER has established, and/or to point the reader to other possible relevant resources.