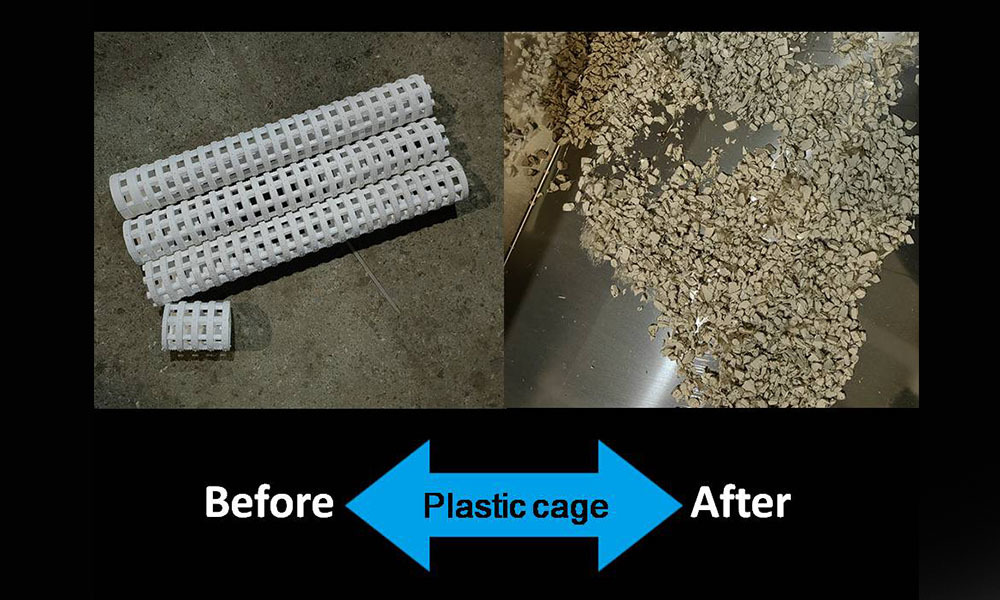

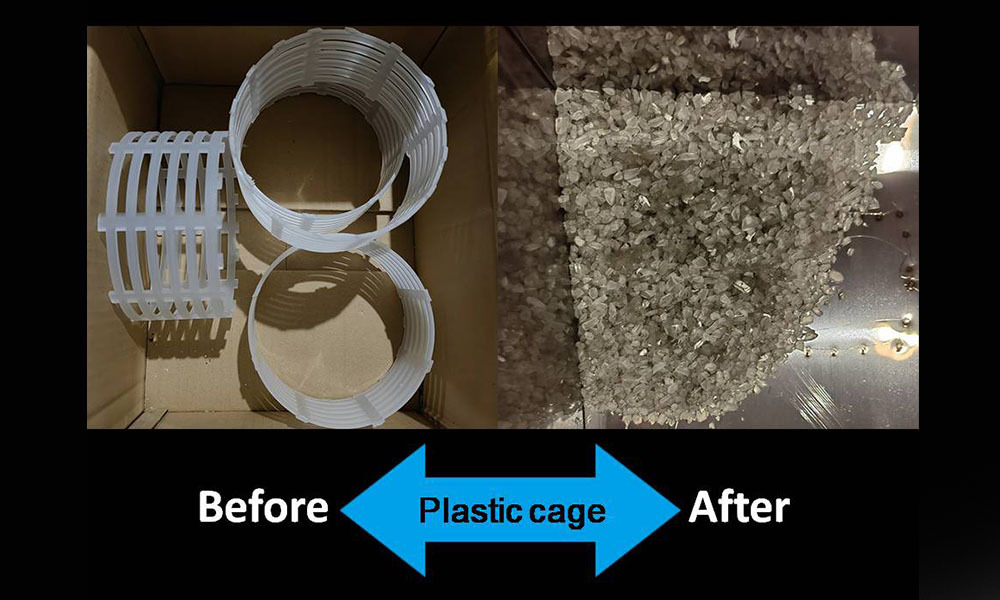

A plastic cage shredder is a specialized piece of equipment used in the recycling industry to break down plastic cages, containers, or other large plastic objects into smaller, more manageable pieces.

Plastic Cages Recycling

Recycling plastic cages can be a sustainable practice that helps reduce waste and minimize the environmental impact of these items. Here are steps to recycle plastic cages:

1. Collection and Sorting: a) Begin by collecting plastic cages from various sources such as industrial facilities, warehouses, or agricultural operations; b) Sort the cages based on their material type, as they may be made from different types of plastic (e.g., HDPE or PP). Proper sorting is crucial for effective recycling.

2. Cleaning: a) Clean the plastic cages to remove any contaminants, dirt, or residues. This can involve using water, detergents, or specialized cleaning equipment; b) Properly cleaned cages are easier to recycle and result in higher-quality recycled material.

3. Shredding or Granulation: Depending on the recycling facility's capabilities, the plastic cages may need to be shredded or granulated into smaller pieces. This step is essential for processing and melting the plastic.

4. Melting and Extrusion: The shredded or granulated plastic is then melted and extruded into a form suitable for recycling. This may involve heating the plastic to a specific temperature and using molds or extrusion machines to shape it.

5. Quality Control: During the melting and extrusion process, quality control measures should be in place to ensure that the resulting plastic material meets the desired standards. This includes checking for impurities, color consistency, and material strength.

6. Reproduction or Repurposing: a) The recycled plastic material can be used in various applications, depending on its quality and characteristics; b) It can be used to manufacture new plastic cages, plastic products, construction materials, or other items; c) In some cases, recycled plastic may be combined with virgin plastic to create products with specific properties.

7. Distribution and Sale: The recycled plastic or products made from recycled plastic can be distributed to manufacturers or consumers for use in various applications.

8. Reduce and Reuse: Encourage the reduction and reuse of plastic cages wherever possible to minimize the need for recycling. Consider options like returnable and reusable packaging systems.

Plastic cage shredders play a crucial role in improving recycling efficiency by reducing large plastic items into smaller, uniform pieces. This makes it easier to process and recycle the plastic material. Shredding plastic cages significantly reduces their volume, making it more cost-effective to transport and store the shredded material. This is especially important in recycling operations where space and logistics are concerns. Using plastic cage shredders contributes to environmental sustainability by diverting plastic waste from landfills and reducing the demand for new plastic production.

Plastic cage shredders come in various sizes and capacities, depending on the specific recycling needs of a facility. Choosing the right size and type of shredder is essential for optimal performance.

Explore more plastic size reduction solutions from SINOBALER plastic balers.