Horizontal Pipe Shredder

Size reduction for large plastic pipes, paper cores and rubber tubes. These horizontal pipe shredders are commonly used in industrial settings, recycling facilities, or waste management processes to break down large objects into smaller pieces for easier handling, transportation, or recycling. They play a crucial role in recycling efforts by reducing the volume of materials and preparing them for further processing or recycling.These blades shred the pipes into smaller pieces, depending on the desired output size.

- Product description

- Main Features

- Application

- Specifications

-

Product description

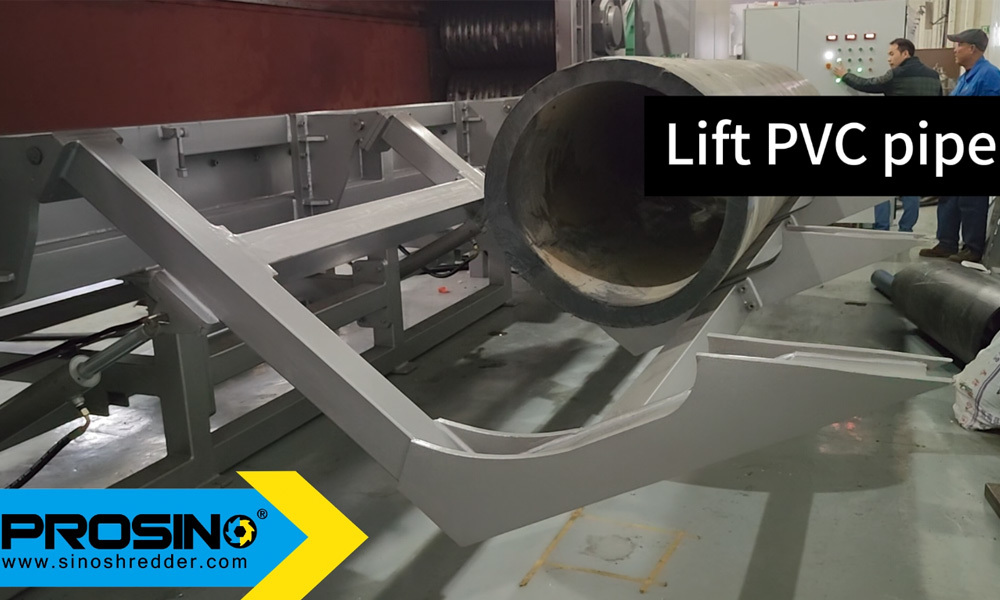

Prosino PPS Series Horizontal Pipe Shredder is especially designed for the efficient size reduction of various types of pipes & paper cores. Normally these materials are big in diameter, thick in wall and long in length which cannot be well handled by normal vertical-feeding pipe shredders. This machine consists of a shredding head and a hydraulic driven feeding trough which opens/close automatically under auto operation mode or just by simple operation on buttons under manual operation mode. After putting the pipes/cores into the loading chamber, the long stroked hydraulic cylinder will horizontally push the pipes towards the spinning cutting rotor for shredding.

The shredder utilizes square shaped blades with four sides. And the blade can be turned after one side is worn out. You can use the new side, which means longer life of usage of the blades. The feeding chamber of the machine can accommodate pipes with length up to 6000mm without pre-cutting, eliminating the additional labor cost and effort involved in pre-handling prior shredding. Each time you can put a few pipes together for shredding. You can just directly put the pipes as they are into the machine for straightforward size reduction. With advanced PLC controlling system and an integrated control panel, operation of this machine is as simple and user’s friendly as it can be.

The primary use of this horizontal pipe shredder is for efficient shredding of large sized pipes or bundles of smaller pipes made from HDPE, PP, PVC, etc. Besides shredding plastic pipes, this machine can also be available for the size reduction of rubber tubes and pipes, as well as paper cores and tubes. If you are in the recycling business of these waste pipe and core material, then this horizontal pipe shredder is a very good choice for you.

Inquire now on our existing model or contact us for a customized shredding solution. View SINOBALER baling machines

Key words:- Horizontal Pipe Shredder

- Pipe Shredder

- large pipe shredder

-

Main Features

- Hydraulic-driven press plate

To push the objects closely to the cutting rotor for efficient shredding - Independent quadrate blades

Easy to be replaced or turned to other sides for repeated use - PLC control

Making it easier for fault diagnosis and maintenance - Cooling system

For effectively cooling down hydraulic oil temperature so as to protect machine

- Hydraulic-driven press plate

-

Application

- PLASTIC PIPES

PE pipe, PVC pipe, PP pipe, ABS pipe, large diameter HDPE pipe - RUBBER TUBES & PIPES

- PAPER CORSE/TUBES

- PLASTIC PIPES

-

Specifications

Model Hopper Inlet Active rotor diameter Main motor power Weight(approx) Length Width PPS-800 6860 mm

(270 inch)

800 mm

(31 inch)

ø800 mm

(ø31.5 ")

2 * 37 kw

(2 * 50 HP)

11000 kg

(22000 lbs)

PPS-1000 6700 mm

(264 inch)

1000 mm

(39 inch)

ø980 mm

(ø38.6 ")

2 * 45 kw

(2 * 60 HP)

16000 kg

(35200 lbs)

PPS-1500 6700 mm

(264 inch)

1400 mm

(55 inch)

ø1430 mm

(ø56.3 ")

2 * 55 kw

(2 * 75 HP)

25000 kg

(55000 lbs)

KEYWORD

All Shredders and Granulators

Categories by Number of Rotor

Categories by Function

Auxiliaries

Related video

Paper Tube Shredder, Horizontal Paper Tube Shredding Machine

HDPE Pipe Shredder, HDPE Tube Shredder, HDPE Pipe Shredding Machine, HDPE Tube Shredding Machine

PVC Pipes Shredder, PVC Pipes Shredding Machine

Shredders and Granulators

RELATED EQUIPMENT AND ACCESSORIES

I agree that my personal data collected by PROSINO is processed, used and stored in compliance with data protection exclusively for the purpose of processing my request.

SINOSHREDDER PRIVACY POLICY

We collect information from you when you fill out an inquiry or contact form. When submitting the form on our site, you may be asked to enter your name and contact details such as: e-mail address, mailing address and/or phone number, etc. Alternatively, you can choose not to complete our forms and visit our site anonymously. Any of the information we collect from you may be used to help us to better respond to your individual needs, and/or enable us to more effectively respond to your customer service requests and support needs. The email address you provided may also be used to send you information and updates pertaining to your inquiry and/or order, in addition to receiving occasional company news, updates, related product or service information, etc.

PROSINO SHREDDER does not sell, trade, or otherwise transfer to outside parties your personally identifiable information. This does not include trusted third parties who assist us in operating our website, conducting our business, or servicing you, so long as those parties agree to keep this information confidential. We may also release your information when we believe release is appropriate to comply with the law, enforce our site policies, or protect ours or others rights, property, or safety.

By using our site, you consent to our online privacy policy. If we decide to change our privacy policy, we will post those changes on this page. If you have any questions or concerns regarding our privacy policy, please e-mail prosino@sinobaler.com or mail your question to us at 1206 Yinzhou Shanghui Nan Lou, 1299 Yinxian Avenue, Yinzhou District, Ningbo 315192, P.R. China.

EXTERNAL LINKS & DISCLAIMER

Our web site has links to many other organizations with their permission. Upon leaving the SINOSHREDDER web site, you are subject to the privacy policy of the new site which are not under our control. PROSINO SHREDDER is not responsible for the content of any linked site or any link contained in a linked site. These links are provided to you as a service for you to better understand the different business relationships that SINOSHREDDER has established, and/or to point the reader to other possible relevant resources.