Single Rotor Shredder – Swing Arm

It is a robust industrial machine designed for effective shredding of various materials such as plastic film, cardboard, wood, woven bag etc. The key feature of this shredder is its swing arm, which allows for a versatile and efficient shredding process. The swing arm mechanism enables the machine to accommodate a wide range of materials and sizes. This design is particularly effective for handling bulky and irregularly shaped items.

- Product description

- Main Features

- Application

- Specifications

-

Product description

PROSINO PS-S-B series Single Rotor Shredders are heavy duty size reduction machines suitable for processing a wide variety of materials including plastic, paper, cardboard, wood, textile, etc. Different from traditional single shaft shredder which is equipped with a horizontal hydraulic pusher, this swing arm type single rotor shredder adopts a hydraulic-driven swing pusher which automatically forces material towards the cutting rotor for achieving the most efficient size reduction performance.

A replaceable screen is mounted underneath the cutting rotor for controlling the shredded material below the screen mesh size. The rotary cutter features with auto reverse function which kicks in anytime in case of some stubborn material or excessive quantities of material that cannot be shredded. This automatic reverse function not only protects machine itself from overloading and breaking, but also guarantees a continuous and streamlined shredding operation. Controlled by PLC system, operation of this single rotor shredding machine is straight-forward, simply press buttons on control panel to control every movement. And “auto mode” can be available for automatic operation to increase working efficiency and meanwhile save labor.

See how swing-arm shredder is working in RDF line and how it connects to granulator and baler in whole production line.

Inquire now on our existing model or contact us for a customized shredding solution. View SINOBALER baling machines

Key words:- single shaft shredder

- one rotor shredder

- single rotor shredder

-

Main Features

- Hydraulic-driven swing pusher

To push the objects close to the rotary cutters to achieve efficient shredding performance - Screen mesh mounted at the outlet

For controlling the output granules below certain size. Size of the screen mesh can be customized according to your need - Easy replacement of blades

For minimizing downtime and promoting work efficiency - Blades can be repeatedly used for 4 times by changing the fixing side

Greatly saving operation cost and reducing downtime - Blades made of high-resistant steel

Ensures longest usage times - PLC control

Making it easier for fault diagnosis and maintenance - Rotor Auto-reverting Function

To protect machine when material gets stuck in the cutting chamber - Cooling system

For cooling down hydraulic-oil temperature in high ambient temperature, ensuring machine running in good condition - Easy operation

Simply press the buttons on the control panel to control every movement, and “auto mode” can be selected on the control panel for fully automatic operation

- Hydraulic-driven swing pusher

-

Application

- PLASTIC

Plastic film, plastic woven bags, drum/barrel, plastic pallet, TV/computer shell, plastic pipes, purgings - RUBBER

Rubber sheet, rubber pad, car tires, rubber tube, rubber rolls, rubber seals - PAPER WASTE

Cardboard, newspaper, office paper, kraft paper, paper core, cardboard tube, paper packaging material - WOOD

Lumber, wooden pallet, wooden boards, wooden sheet, tree branches - E-WASTE

Circuit board, hard disk, waste computer/TV, cable, electric elements, household appliance, office appliance - TEXTILE

Curtain, used clothes, quilt, carpet, rag, waste car-seat

- PLASTIC

-

Specifications

Model Hopper Inlet Active rotor diameter Main motor power Weight(approx) Length Width PS-S-B-48120 2000 mm

(79 inch)

1550 mm

(61 inch)

ø480 mm

(ø18.9 ")

75 kw

(100 HP)

6800 kg

(14960 lbs)

PS-S-B-48150 2000 mm

(79 inch)

1850 mm

(73 inch)

ø480 mm

(ø18.9 ")

90 kw

(125 HP)

8500 kg

(18700 lbs)

PS-S-B-48200 2000 mm

(79 inch)

2300 mm

(93 inch)

ø480 mm

(ø18.9 ")

2 * 55 kw

(2 *75 HP)

10500 kg

(23100 lbs)

PS-S-B-48250 2000 mm

(79 inch)

2850 mm

(112 inch)

ø480 mm

(ø19 ")

2 * 75 kw

(2 * 100 HP)

12800 kg

(28160 lbs)

KEYWORD

All Shredders and Granulators

Categories by Number of Rotor

Categories by Function

Auxiliaries

Related video

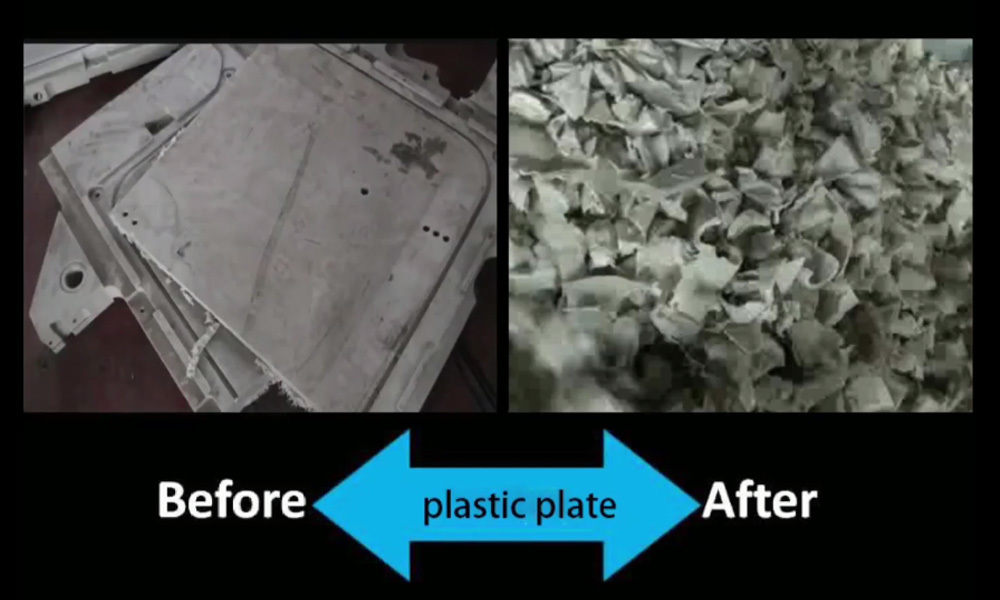

Plastic Plate Swing-arm Single Shaft Shredder, Plastic Plates Shredders, Plastic Plate Shredding Machine

RDF Shredder, RDF Shredding Machine, Refuse Derived Fuel Shredder

Coconut Husk Shredder

The above machine can shred/granulate

Shredders and Granulators

RELATED EQUIPMENT AND ACCESSORIES

I agree that my personal data collected by PROSINO is processed, used and stored in compliance with data protection exclusively for the purpose of processing my request.

SINOSHREDDER PRIVACY POLICY

We collect information from you when you fill out an inquiry or contact form. When submitting the form on our site, you may be asked to enter your name and contact details such as: e-mail address, mailing address and/or phone number, etc. Alternatively, you can choose not to complete our forms and visit our site anonymously. Any of the information we collect from you may be used to help us to better respond to your individual needs, and/or enable us to more effectively respond to your customer service requests and support needs. The email address you provided may also be used to send you information and updates pertaining to your inquiry and/or order, in addition to receiving occasional company news, updates, related product or service information, etc.

PROSINO SHREDDER does not sell, trade, or otherwise transfer to outside parties your personally identifiable information. This does not include trusted third parties who assist us in operating our website, conducting our business, or servicing you, so long as those parties agree to keep this information confidential. We may also release your information when we believe release is appropriate to comply with the law, enforce our site policies, or protect ours or others rights, property, or safety.

By using our site, you consent to our online privacy policy. If we decide to change our privacy policy, we will post those changes on this page. If you have any questions or concerns regarding our privacy policy, please e-mail prosino@sinobaler.com or mail your question to us at 1206 Yinzhou Shanghui Nan Lou, 1299 Yinxian Avenue, Yinzhou District, Ningbo 315192, P.R. China.

EXTERNAL LINKS & DISCLAIMER

Our web site has links to many other organizations with their permission. Upon leaving the SINOSHREDDER web site, you are subject to the privacy policy of the new site which are not under our control. PROSINO SHREDDER is not responsible for the content of any linked site or any link contained in a linked site. These links are provided to you as a service for you to better understand the different business relationships that SINOSHREDDER has established, and/or to point the reader to other possible relevant resources.