Vulcanized rubber, often found in tires, industrial seals, gaskets, and various automotive parts, is one of the most durable and resilient materials known to man. However, this durability also makes it challenging to recycle and dispose of efficiently. Traditional methods of rubber disposal, such as landfilling or incineration, have significant environmental drawbacks, contributing to pollution and the depletion of natural resources.

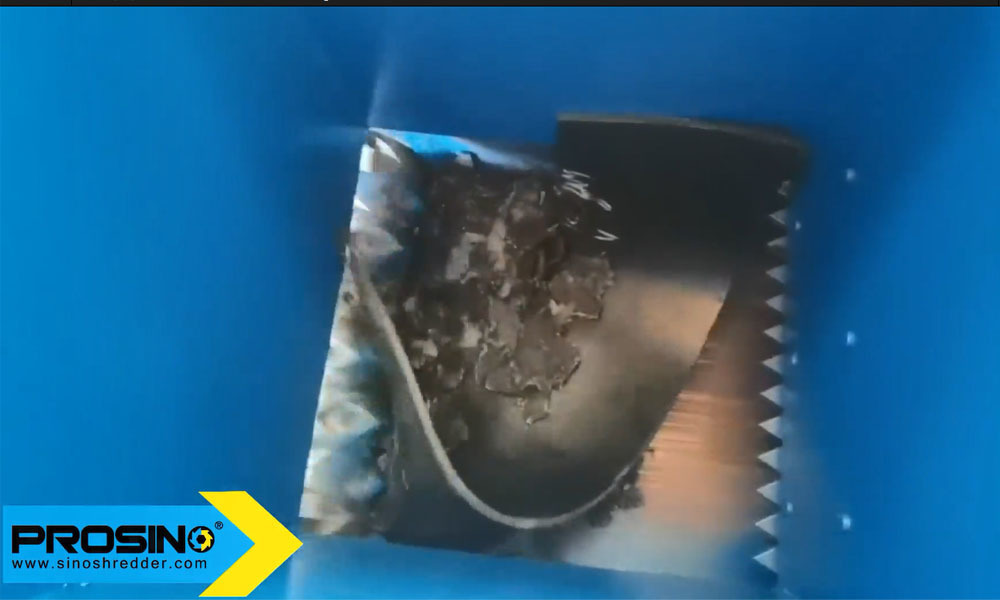

This is where vulcanized rubber shredding machine comes into play. These specialized machines play a crucial role in the recycling of vulcanized rubber, enabling it to be repurposed into new products or materials, reducing environmental impact and conserving resources.

What is Vulcanized Rubber?

Vulcanized rubber is rubber that has been chemically treated with sulfur to enhance its strength, elasticity, and durability. The vulcanization process makes the rubber heat-resistant, weather-resistant, and far more stable than untreated rubber. As a result, it is commonly used in the production of tires, industrial seals, hoses, and other heavy-duty products. However, these enhanced properties also make it difficult to shred and process for recycling.

The Need for Shredding Vulcanized Rubber

Given the widespread use of vulcanized rubber, particularly in the form of tires, there is an enormous need for effective recycling solutions. Tires alone are responsible for a large portion of rubber waste, and without proper recycling, they can cause severe environmental problems. Tires take up significant landfill space, and the chemicals released when they decompose can pollute soil and water.

Shredding vulcanized rubber is a critical first step in the recycling process. By breaking down large rubber materials into smaller, more manageable pieces, shredders prepare the rubber for further processing, such as granulation or grinding into crumb rubber. These smaller pieces can then be reused in a variety of applications, from new rubber products to artificial turf, rubberized asphalt, and more.

Advantages of Using Vulcanized Rubber Shredding Machines

- Environmental Benefits:

Shredding vulcanized rubber allows for recycling, reducing the need for landfill disposal. This significantly lowers the environmental impact of rubber waste. The shredded material can be repurposed into new products, thus reducing the demand for raw materials and conserving natural resources. - Energy Efficiency:

Shredding rubber into smaller pieces helps reduce the energy required for subsequent processing stages, such as grinding or granulating. Smaller pieces of rubber are easier to process, making the entire recycling operation more energy-efficient. - Increased Recycling Potential:

Shredded rubber can be used in various industries, including construction, automotive, and sports. For example, crumb rubber can be used in the production of rubberized asphalt, which provides a longer-lasting and more durable road surface. Shredded rubber is also used in manufacturing products like rubber mats, flooring, and even new tires, promoting a circular economy. - Cost Savings:

Recycling vulcanized rubber reduces the need for raw material extraction and the associated costs of production. It also helps reduce disposal costs by diverting waste from landfills and incineration plants. For businesses involved in rubber waste management, investing in a vulcanized rubber shredder can lead to long-term cost savings. - Improved Safety:

Shredding vulcanized rubber can help mitigate fire hazards associated with large piles of rubber waste. By breaking down rubber into smaller, manageable pieces, the material is less likely to catch fire and cause a large-scale blaze, which is a common risk with tires and other rubber products.

Applications of Shredded Vulcanized Rubber

Once vulcanized rubber has been shredded, it can be used in a wide range of applications:

- Crumb Rubber: Shredded and processed rubber can be converted into crumb rubber, which is used in products like playground surfaces, sports tracks, artificial turf, and rubberized asphalt.

- Rubber Mats and Flooring: Shredded rubber is used to create durable and resilient rubber mats, flooring, and tiles for industrial, commercial, and residential use.

- Recycled Rubber Products: Many products, such as mats, seals, gaskets, and even new tires, can be manufactured using recycled rubber materials.

- Construction and Road Maintenance: Rubberized asphalt is used for road paving, as it improves road durability, reduces noise, and enhances the longevity of road surfaces.

Reach out to PROSINO team for your right rubber shredder.

Quick links: