Browse our shredder pictures and granulator pictures by selecting the machine type on the left side. You are also welcome to click images or names of PROSINO Shredders and Granulators incl Single Shaft Shredder, Double Shaft Shredder, Mini Granulator, Medium and Large Granulator, Pipe Granulator and Shredding & Granulating Integrated Unit for more detailed size reduction solutions. View more size reduction machines.

All Shredders and Granulators

Browse our shredder pictures and granulator pictures by selecting the machine type on the left side. You are also welcome to click images or names of PROSINO Shredders and Granulators incl Single Shaft Shredder, Double Shaft Shredder, Mini Granulator, Medium and Large Granulator, Pipe Granulator and Shredding & Granulating Integrated Unit for more detailed size reduction solutions. View more size reduction machines.

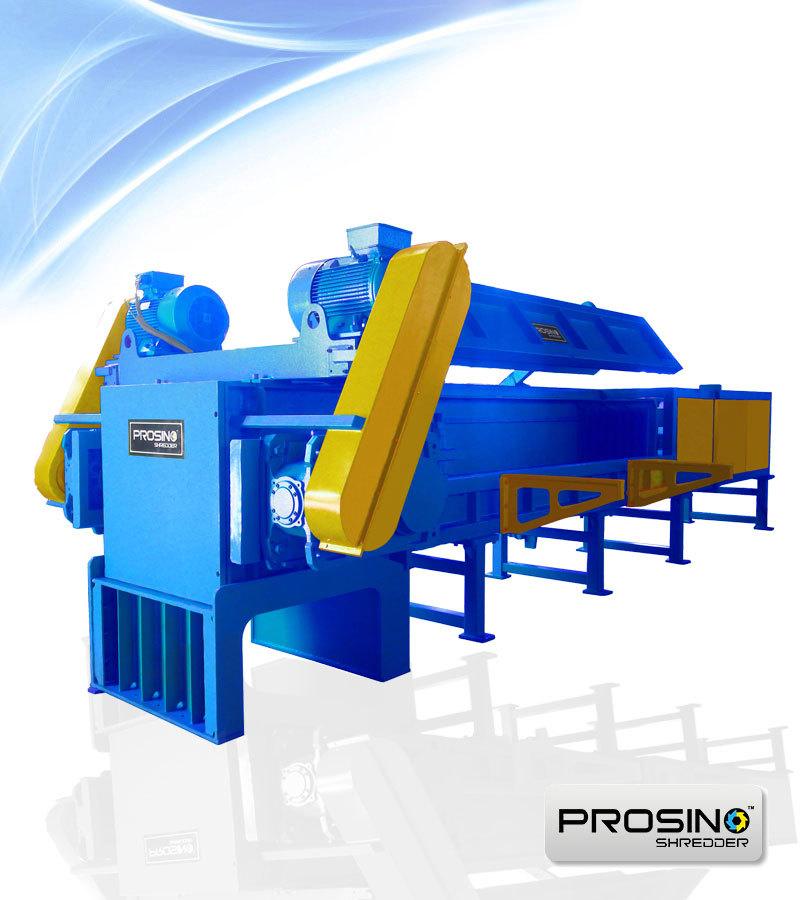

Shredding & Granulating Combined Machine for Long Planks

The Shredding & Granulating Combined Machine for Long Planks offers an efficient, durable, and flexible solution for shredding long wooden boards and foam boards. Its customizable design, convenient maintenance, and optional features make it a top choice for industries requiring efficient material processing. By combining the shredding and granulating functions, this machine ensures that the boards are not only broken down into smaller sizes but also granulated into fine particles, ready for further recycling or processing.

Wood Pallet Shredder

The machine includes the shredder itself and also a screw conveyor to deliver the discharge material. Production capacity is 20-30 pallets per hour. It is especially designed for the size reduction of wood pallets and plastic pallets. This pallet shredder plays a crucial role in recycling and waste management by transforming used or obsolete pallets into smaller, more manageable pieces. The shredded material can be repurposed for various applications, such as producing wood chips or mulch, contributing to resource recovery and sustainability.

Pipe Granulator

Size reduction for plastic pipes and sheets. This equipment is commonly used in recycling and waste management processes, particularly in industries where plastic pipes or tubes need to be efficiently reduced in size for further processing. Pipe Granulators contribute to waste reduction and recycling efforts by transforming all kinds of pipes into manageable and uniform particles. These granules can be utilized for various applications, such as in the manufacturing of new plastic products or materials.

Silent Granulator

Size reduction for plastics and corrugated board trims. This specialized equipment is equipped with innovative features to minimize vibrations and sound emissions during the granulation process. Designed with noise-sensitive settings in mind, such as manufacturing facilities located near office spaces or research labs, silent granulators offer a balance between effective material processing and reduced noise pollution. The granules produced by silent granulators can be used for recycling or further manufacturing processes, making them valuable tools in industries where noise control is a crucial consideration.

Small Sized Granulator For Plastics and Foils

Size reduction for hollow plastic containers and plastic foils. Despite its small footprint, this granulator is equipped with robust cutting mechanisms specifically engineered for the effective breakdown of plastics and foils. It is capable of transforming plastic waste and thin foils into uniform granules, facilitating recycling and waste reduction efforts. It is user-friendly, allowing for easy operation and maintenance. The granulated output produced by this machine can be utilized in various applications, contributing to sustainable practices by repurposing plastic waste and foils.

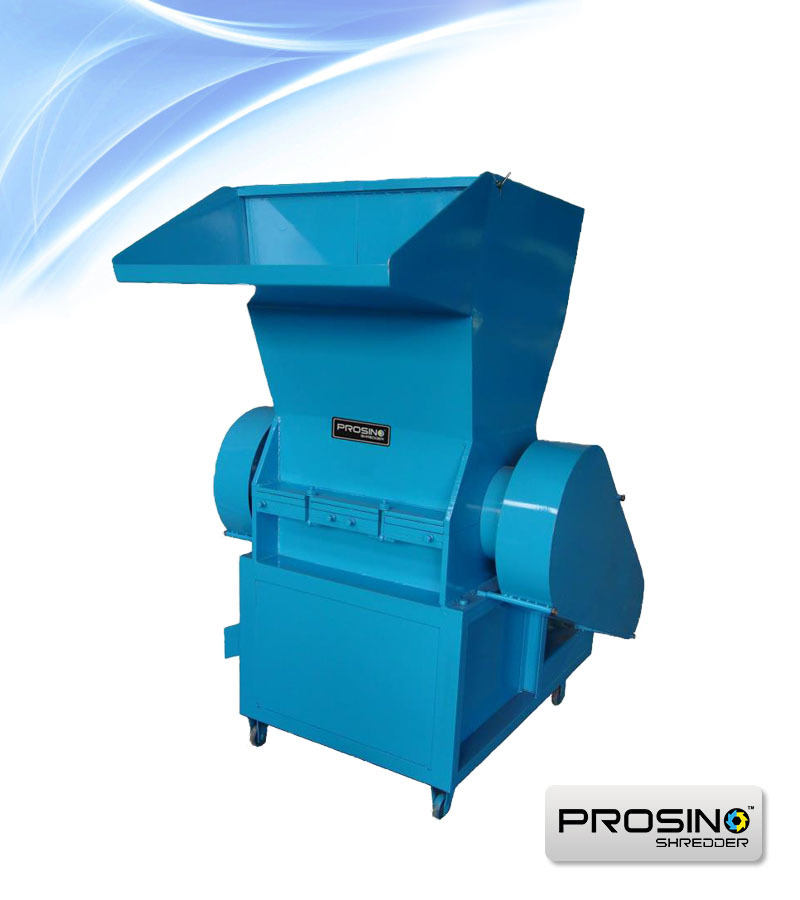

Small Sized Plastic Granulator / Plastic Grinder

Size reduction for soft plastics, molding plastic such as purgings etc. It is a compact and efficient industrial machine designed for the granulation of plastic materials in smaller-scale operations. Its size and portability make it particularly suitable for settings where space is limited, such as laboratories, small manufacturing facilities, or research environments. The machine's design emphasizes user-friendliness, allowing for easy operation and maintenance.

Medium and Large Granulator

A Medium and Large Granulator represents a robust and versatile industrial machine designed for efficient size reduction of various materials on a medium to large scale. These granulators are engineered to handle diverse materials, including plastics, rubber, paper waste, wood, and more, making them essential in recycling facilities and industrial settings. They are capable of processing substantial volumes of materials, breaking them down into uniform granules.

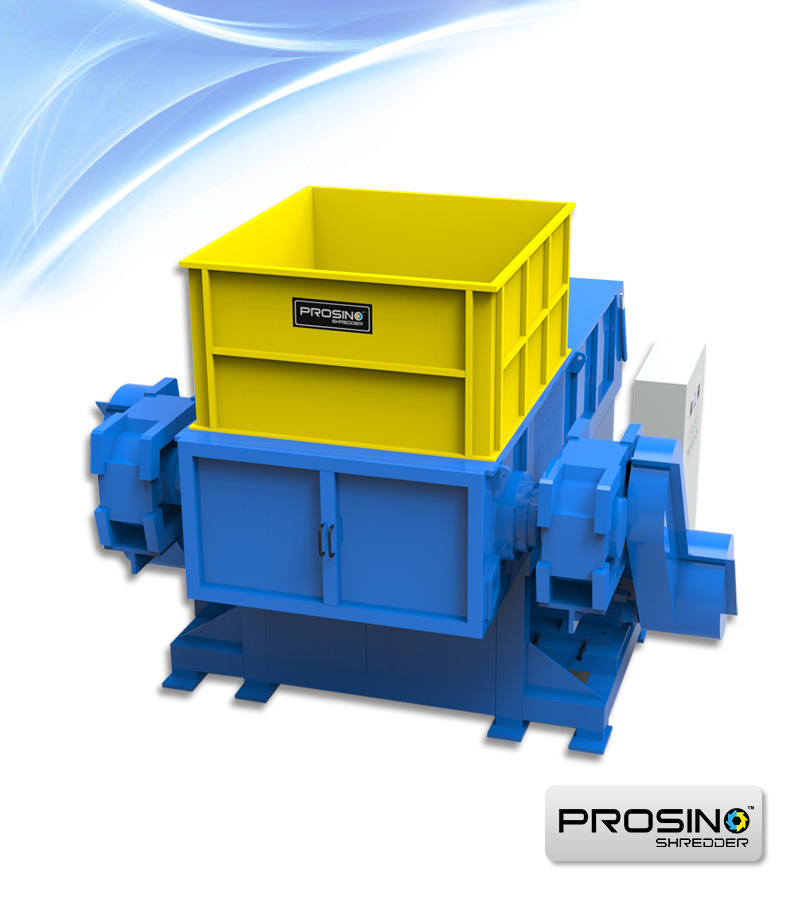

Shredding & Granulating Integrated Unit

In this unit, a shredder component efficiently breaks down larger materials into smaller, more manageable pieces. Subsequently, a granulator component refines the shredded material into uniform granules, optimizing its usability for various applications. This integration of shredding and granulating functions ensures a thorough reduction of materials while maintaining a streamlined and space-efficient operation. It is ideal to recycle large plastic purgings, heavy plastic tubes, plastic buckets/drums, etc.

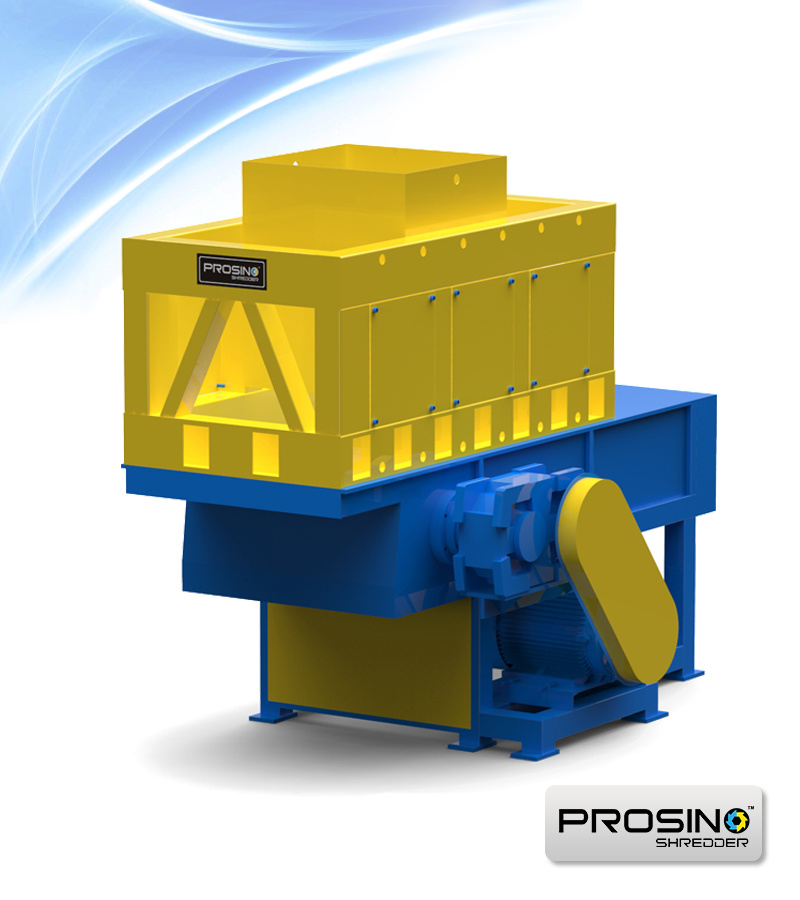

Twin Shaft Shredder with Shearing Blades – Dual Motor

This shredder is characterized by its dual shafts, each equipped with shearing blades, and the use of two powerful motors. The dual motor configuration enhances the machine's power and torque, allowing it to efficiently process diverse and challenging materials. Their versatility and high-performance capabilities make them effective in handling materials such as plastics, tires, cardboard tube, wooden pallets, TV cases and steel drum, and more.

Double Shaft Shredder with Shearing Blades – Single Motor

It is a robust industrial machine engineered for efficient and versatile shredding of various materials.The shearing blades on the dual shafts work in tandem to cut and tear through materials, ensuring thorough and consistent shredding. The single motor driving both shafts simplifies the system while maintaining a high level of performance. This type of shredder is particularly effective in breaking down bulky items, plastics, metals, wood, rubber, paper and other recyclable materials.

Horizontal Pipe Shredder

Size reduction for large plastic pipes, paper cores and rubber tubes. These horizontal pipe shredders are commonly used in industrial settings, recycling facilities, or waste management processes to break down large objects into smaller pieces for easier handling, transportation, or recycling. They play a crucial role in recycling efforts by reducing the volume of materials and preparing them for further processing or recycling.These blades shred the pipes into smaller pieces, depending on the desired output size.

Vertical Single Shaft Pipe Shredder

Size reduction for long or thick plastic pipes. This shredder is engineered with a single shaft that houses powerful cutting blades or knives, strategically positioned to effectively reduce large pipes into smaller, manageable pieces. This type of shredder is particularly effective in breaking down long pipes or tubes into smaller sections, simplifying the recycling process. The shredded output can be repurposed for recycling or further processing, contributing to sustainable practices by reducing the volume of waste and facilitating the reuse of materials.

Single Shaft Shredder – Single Motor

Size reduction for molding plastic, purgings, cardboard, wood, E-waste etc. The key feature of this shredder is its single motor driving the rotor, streamlining the shredding process and enhancing operational simplicity. It is commonly used in recycling facilities, waste management operations, and industrial settings where the reduction of materials is a crucial step in the processing chain. The shredded output is often recycled or further processed for various applications, contributing to sustainable practices and waste minimization.

Single Shaft Shredder – Dual Motor

Size reduction for molding plastic, purgings, cardboard, wood, E-waste etc. A Single Rotor Shredder with Dual Motors is an advanced industrial machine designed for high-performance shredding of diverse materials. The distinctive feature of this shredder is the utilization of two powerful motors to drive the single rotor. The dual motor configuration contributes to increased power and torque, enabling the shredder to effectively process tougher materials with efficiency.

Single Rotor Shredder – Swing Arm

It is a robust industrial machine designed for effective shredding of various materials such as plastic film, cardboard, wood, woven bag etc. The key feature of this shredder is its swing arm, which allows for a versatile and efficient shredding process. The swing arm mechanism enables the machine to accommodate a wide range of materials and sizes. This design is particularly effective for handling bulky and irregularly shaped items.

SINOSHREDDER PRIVACY POLICY

We collect information from you when you fill out an inquiry or contact form. When submitting the form on our site, you may be asked to enter your name and contact details such as: e-mail address, mailing address and/or phone number, etc. Alternatively, you can choose not to complete our forms and visit our site anonymously. Any of the information we collect from you may be used to help us to better respond to your individual needs, and/or enable us to more effectively respond to your customer service requests and support needs. The email address you provided may also be used to send you information and updates pertaining to your inquiry and/or order, in addition to receiving occasional company news, updates, related product or service information, etc.

PROSINO SHREDDER does not sell, trade, or otherwise transfer to outside parties your personally identifiable information. This does not include trusted third parties who assist us in operating our website, conducting our business, or servicing you, so long as those parties agree to keep this information confidential. We may also release your information when we believe release is appropriate to comply with the law, enforce our site policies, or protect ours or others rights, property, or safety.

By using our site, you consent to our online privacy policy. If we decide to change our privacy policy, we will post those changes on this page. If you have any questions or concerns regarding our privacy policy, please e-mail prosino@sinobaler.com or mail your question to us at 1206 Yinzhou Shanghui Nan Lou, 1299 Yinxian Avenue, Yinzhou District, Ningbo 315192, P.R. China.

EXTERNAL LINKS & DISCLAIMER

Our web site has links to many other organizations with their permission. Upon leaving the SINOSHREDDER web site, you are subject to the privacy policy of the new site which are not under our control. PROSINO SHREDDER is not responsible for the content of any linked site or any link contained in a linked site. These links are provided to you as a service for you to better understand the different business relationships that SINOSHREDDER has established, and/or to point the reader to other possible relevant resources.